With some applications like adhesives and coatings, relative temperature readings can provide visual characteristics or features that can provide valuable information about the quality of the part.

Temperature is a critical factor in producing many parts and products we rely on daily. From plastic and metal welding processes to injection molding and adhesive and coating applications, the ability to monitor temperature is critical to ensure all these parts or products produced meet quality standards.

That’s why we tell manufacturers looking to deploy machine vision solutions for inline quality monitoring on temperature-sensitive applications to “go thermal”. Thermal cameras have emerged as a powerful data source for manufacturers looking to improve quality by adopting inline defect and process monitoring.

Before we discuss the importance of camera selection, solution integration and solution management software, let’s look at what makes thermal imaging stand out as the best option for manufacturers looking to deploy AI-enabled, inline quality monitoring.

Why Thermal Imaging?

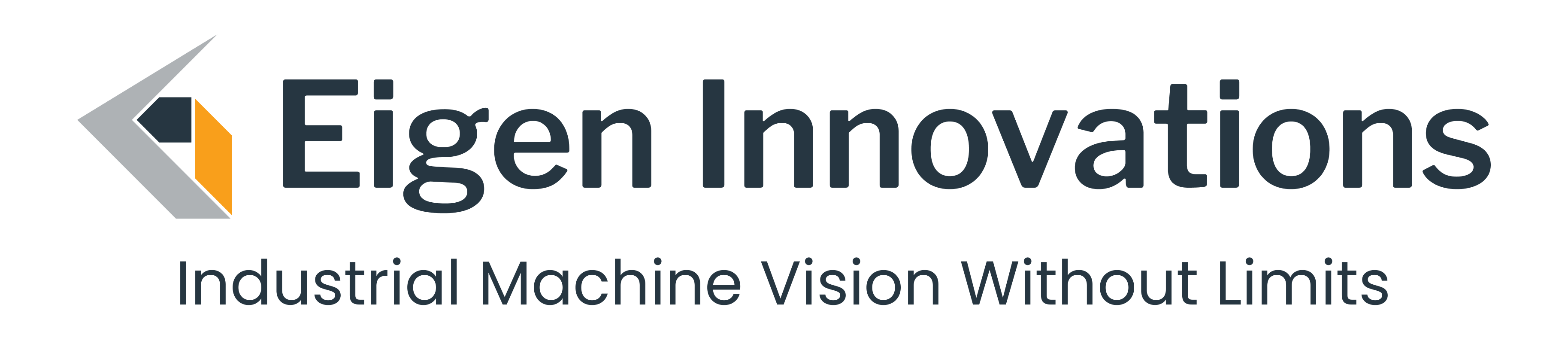

Inspection models perform best when they can focus on what they’ve been trained to see and detect. Removing noise and backgrounds from thermal images makes training models easier as the defects are clearly defined.

Thermal imaging offers three significant advantages for building AI-powered datasets required for delivering inline inspections.

- Resolution Sizes and Data Quality

Thermal cameras have a variety of resolution sizes and configurations. They can operate at 30 or 60 hertz with smaller resolutions and image sizes. Generally, this would mean poor image quality, however, thermal cameras excel at providing more accurate data at lower resolutions. This allows for more efficient image processing, faster inference times, and efficient image acquisition and storage. - Resilience to Environmental Changes

One of the standout features of thermal cameras is their resilience to environmental changes. Factory lighting conditions can create shadows and reflections that adversely impact image capture. Thermal cameras measure heat instead of relying on light. That means they can perform optimally in various lighting conditions, including complete darkness. This capability eliminates the need for complex lighting setups. - Relative Temperature and Background Removal

In some quality management programs, the ability to measure relative temperature is sufficient. Our experience deploying thermal cameras shows that AI models can be effectively trained using relative temperatures without requiring precise temperature measurements. While this approach would not be suitable for all applications, we have deployed it successfully in numerous factories.

Additionally, you can remove background elements (a.k.a. noise) by scaling thermal ranges and setting maximum and minimum thresholds. This allows the model to focus only on the elements it must learn to improve its ability to detect defects.

Select A Thermal Inspection Solution That’s Easy to Manage & Scale

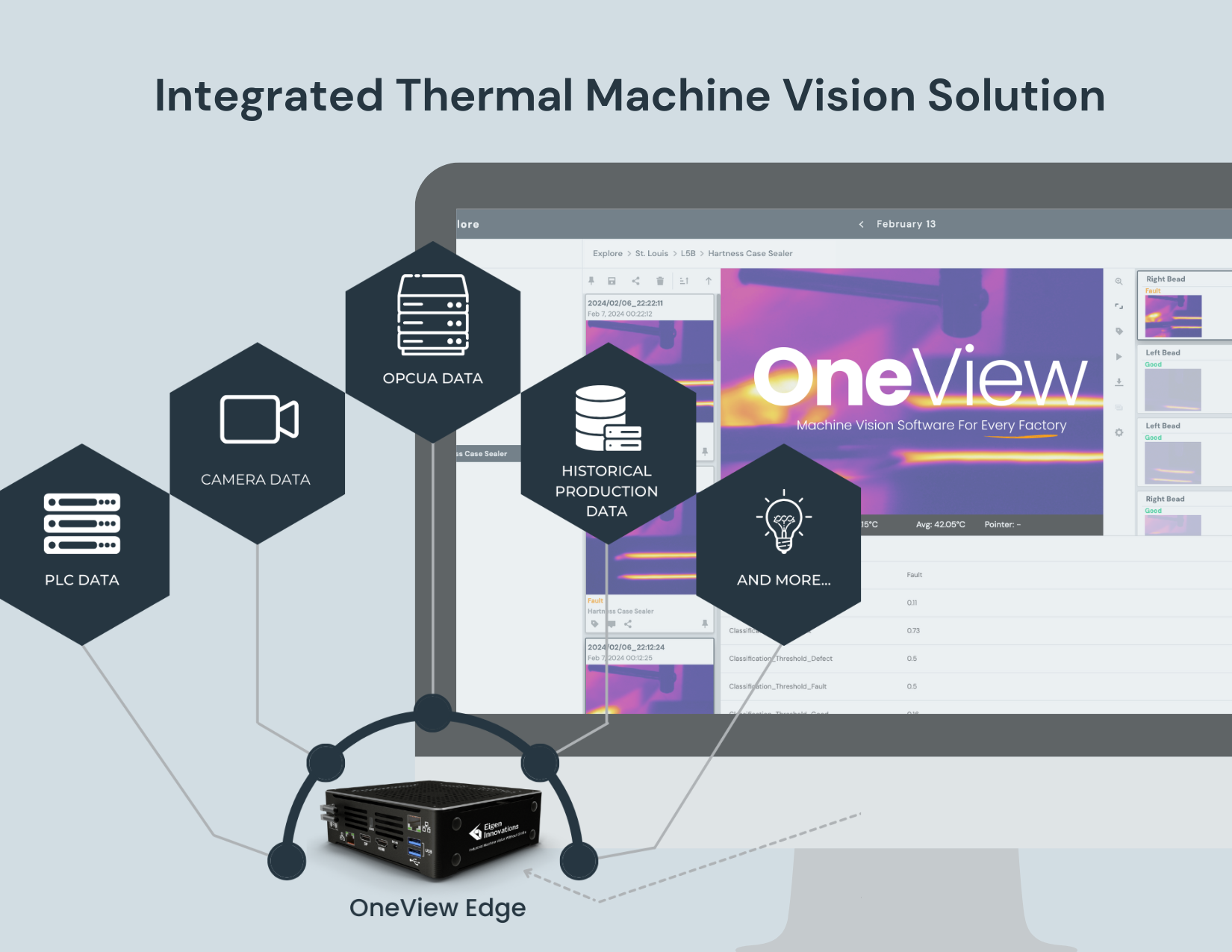

Before you invest in thermal cameras, ensure you’re ready to realize the full value of that investment. While the image data from thermal cameras is a powerful asset, it’s more powerful when consolidated with data from other sources like machines, PLCs and other sensors and when you have software to analyze and use it.

Ensure your solution is designed to integrate with existing infrastructure on your line and generates consolidated, standardized data that makes it easier to deploy and manage AI inspection models.

Integrated thermal inspection solutions capture more than thermal images. They capture all the data needed to deliver the most comprehensive inspection AND provide visibility to variations in the process that may have contributed to or caused quality issues.

The entire solution including creating and deploying those models should be easy to manage and scale. Software from the camera manufacturers is generally limited to hardware management and some image processing. That’s why our OneView software includes tools that help teams from initial configuration and integration through model management and analytics.

Integrating thermal imaging into manufacturing processes is not just adopting new technology. It’s about changing the way you perceive and manage inline quality. With its numerous benefits and proven effectiveness, thermal imaging – combined with powerful software – can be a powerful addition to quality management plans in manufacturing.

Need Thermal? We Can Help

With a team of certified thermographers and software built to leverage the power of thermal imaging, Eigen is well-equipped to address quality issues effectively. We have helped various customers design and deploy solutions featuring thermal cameras. Read more about them here.

We have partnerships with leading camera manufacturers like Teledyne Flir and Optris which further enhance our ability to provide top-tier solutions.

Contact our team here to discuss adding thermal-powered inline inspections to machines today!